Interrupt Design, Not Power

The surge protector, the power strip all seem to have had make-overs to make them more appealing and presentable. Why not apply it to the average UPS units, and then some?

These big black boxes are stuffed under desks everywhere and they play quite the vital role in ensuring that work continues. Many times have these things saved us from not saving in time. While these units are, no doubt, useful, the common uninterruptible power supplies seem to not have changed since the dawn of personal computers. Mainstream units still sport the early 90s design aesthetics and they seem to eat batteries, especially when its most inconvenient. Until there is wireless power transmission, we most likely won’t be able to get away from these things anytime soon.

Here is an idea.

Homes and offices are starting get connected with small networks that monitor and control the utilities and basic fixtures. Lights, outlets, HVAC systems all can be programmed to run when they are needed and how they are needed: at peak efficiency. Feedback from devices provides insight into usage, prevents too much usage and early alerts prevent issues. Modern battery tech has advanced greatly as well. Chargers monitor best charge rates and smart batteries report back usage, charge cycles and other data which helps keep them operating at max capacity for longer.

This UPS would hook right in to the automation networks and the internet. It monitors whatever is plugged in, reports on usage and allows for the control of each outlet. If there is a power loss, the unit would do its best to report on it and log the event. Intelligent battery monitoring and charging is the more important feature. Diligent battery management results in less frequent batt. replacements and provides advance warnings on potential failures. With the UPS being connected to the web, it can send out maintenance requests as needed preventing downtime at the wrong time. This is similar to how a car monitors its own battery health – why not do it with every battery?

If the UPS is going to provide power, why not have it do so over USB as well. Charging USB devices should not be dependent on the power state of the computer nor should it demand yet another thing plugged into the wall. A small USB power point is a way to bring USB charging to the desktop, within easy reach for quick power-ups. The power point grabs power from the same USB ports on the main unit and features small LED lights to show basic UPS status.

The clean design is meant to allow one to keep this UPS on the floor and visible without shame. The unit does also has provisions for wall mounting or even under-table mounting to tuck it out of view. A cradle gets attached where ever desired and the unit clips in.

There is no need to re-invent the wheel. All the technology is readily available. There are UPS units, smart battery tenders, USB chargers and home automation adapters. Why not simplify things a bit, merge and save some wires, plugs, outlets and batteries. After all, less is more.

3D Printing: The Industrial Revolution

It is no secret that the future is here with 3D printing. As Shapeways so well puts it in their slogan “Made in the Future” – this technology is becoming very accessible with an exponential rate of development. The ability to create objects straight from a computer model has revolutionized many engineering and manufacturing processes. Cutting costs and time, 3D printing has also made complex manufacturing more accessible to smaller businesses. By printing prototypes of castings, for example, engineers no longer need to wait on costly cast samples to verify designs. Most of the time, a printed model can be used to confirm and initiate a production run of components (and assist the casting company in making the tooling). 3D printing can even be used to create single-use moulds to “rapid cast” a part if real-world application testing is needed. This process for prototyping and validation can be applied to parts from any material or manufacturing method.

The Revolution

For now, the 3D printing process is mostly used for prototyping or on demand production of smaller, simpler plastic parts or even jewelry. The real impact of the technology is when it is more advanced and cheaper – as any technology becomes with mass market demand and implementation.

Plaster or plastic based 3D printing is most common and cheapest at the moment. Metal based 3D printers are coming online as well, used more in aerospace, defense and advanced research industries – is also the most expensive process. With the evolution of current printers and with the development of “mixed media” ones, factories will be upgrading and replacing existing assembly lines, machinery and tooling with an array of 3D printers.

3D printing will become the faster, cheaper way to make things. Part-specific tooling and machinery will be eliminated and re-tooling will consist of just uploading a new file. Once printers start to mix media – a single printer will be able to produce a whole device, with metallics, plastics and electric circuitry. Ultimately food and human tissue will be printed as well (research is already underway).

Applicable

These are the kinds of technological advances that define the future and impact not just specific industries – but change the world. We are excited to use these systems with our current projects and develop new products to take advantage of 3D printing, not just for prototyping, but as the primary manufacturing technique.

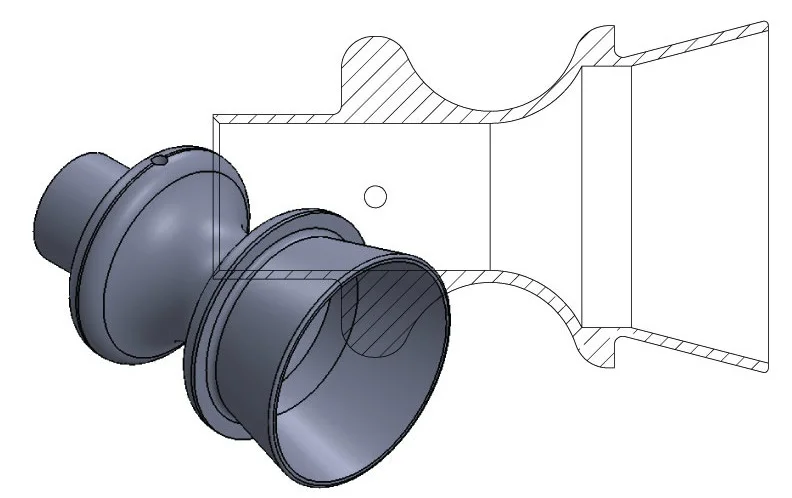

One of our current projects is based around a simple OEM part requiring basic reverse engineering, tweaking and manufacturing out of a different, premium material. Originally made of injection moulded ABS plastic, our client was looking to manufacture it out of aircraft grade aluminum. This change in material would make the part have a more solid, smoother feel with better aesthetics.

We used 3D printing to validate the specs to ensure OEM-like fitment and to get a “feel” for the small aesthetic design changes to the original OEM configuration. Once verified – the production run was started. The final manufacturing process is CNC lathe turning and anodizing for the final finish.

Wells Blog

Duis mollis, est non commodo luctus, nisi erat porttitor ligula, eget lacinia odio sem nec elit. Maecenas faucibus mollis interdum. Nulla vitae elit libero, a pharetra augue.