BMW e90 M3 LSL - Willow Springs

Finally finding some track time as the weekends get a little less busy, or as I merely put off projects. The car is fairly well sorted with some recent updates to the suspension and tires. Bimmerworld lower control arm and trailing arm sphericals installed. Updated front and rear Swift springs for slightly stiffer rates at 10kgf/16kgf. Car has been re-aligned, balanced. Michelin Sport Cup 2 (240) Connected tires were fitted to the Titan7 T-R10 wheels along with the little temp/pressure sensors. I have the Motion Control 2way shocks set up nicely as well.

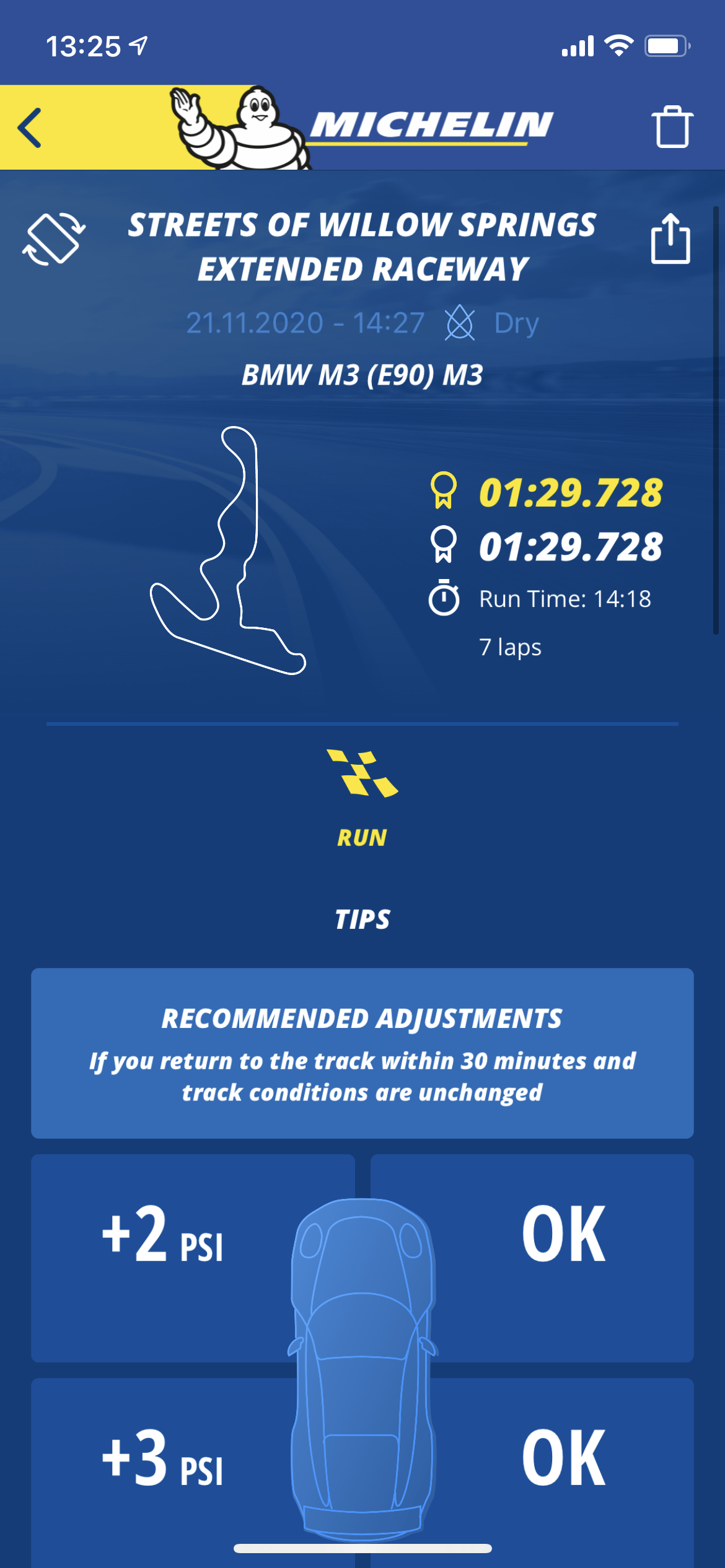

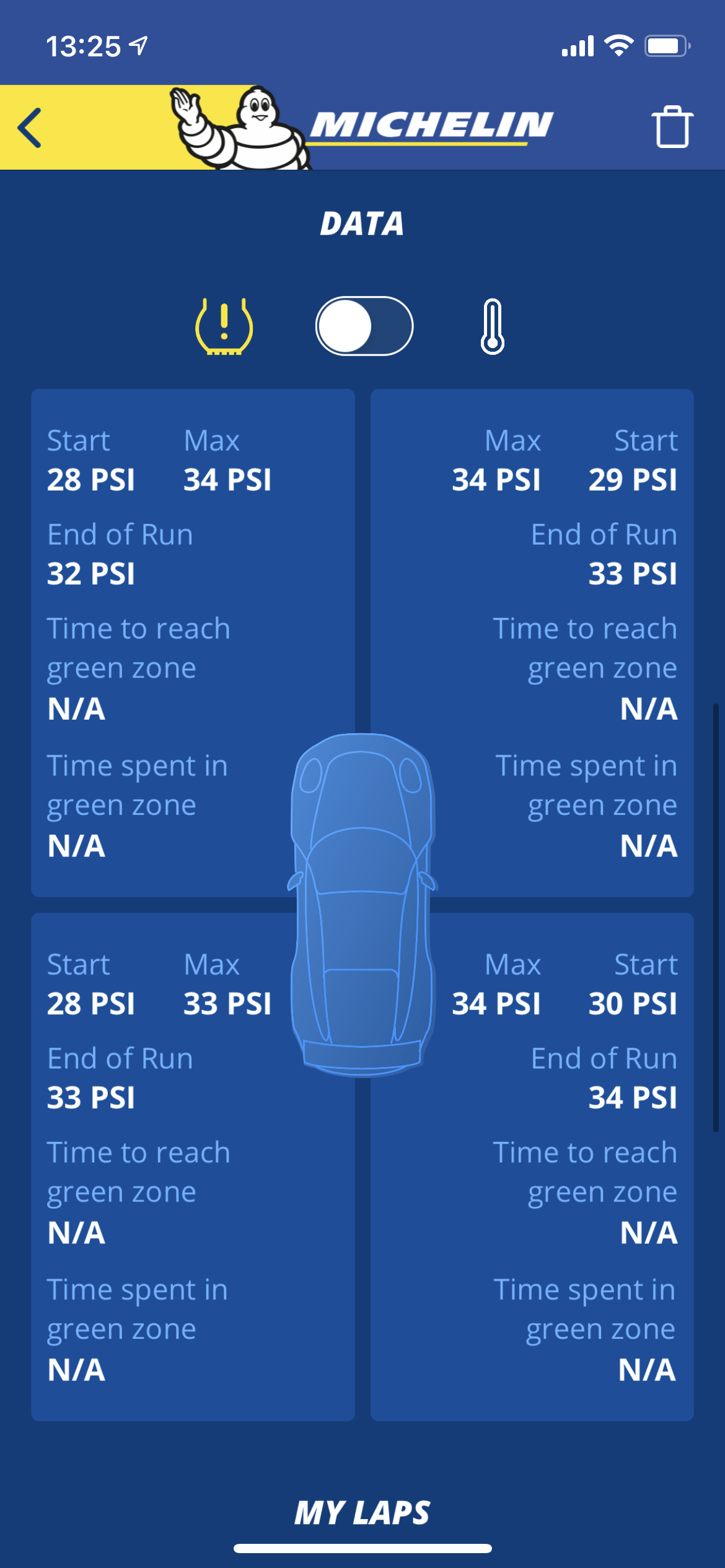

These Michelin are interesting in that they are a Sport Cup 2 tire but in 240 tread wear. The tires are quite soft still, similar to a regular Sport Cup 2. Hoping for some longevity out of these, as I get some new wheels sorted for track use. The Michelins are also the new “Connected Tire” which means they have a small pocket on the inside for a sensor that measures pressure and temp. The sensor comes with a separate 500$ package that is 4 sensors, receiver and a phone mount. The idea is that the sensors are paired to the Michelin Track Connect mobile app, giving you real time temp and pressure data. The data is collected while you are on track with real-time feedback as to state of tires relative to their sweet spot. The app is much like a lap timer, giving you lap times (GPS based) and a course map review of what your tires did and where. Its interesting seeing the temps go up as you run the session. The lap timer is nice but more importantly - you just get a quick readout for temps and pressures.

One of the track events was the Shift-Sector half mile event. This is not the car for it but still fun to stretch it out some. With poor start traction and relatively low effort on my part it ran 135mph or so in the half. To put things into perspective, the McLaren 675LT we bought out ran 187mph at 1000whp and our Porsche GT2 flagship runs 205-208mph consistently at just over 1400whp (6speed to boot)

Two weekends ago got to Streets of Willow at Willow Springs Raceway with SpeedDistrict and the shop, which was sort of the first time the car was set up right. Good tires, shocks tuned with the stiffer springs and etc. This was my first time being at Streets and was a great time learning the track and getting a handle on it. Managed to just dip into 1.29s - lots of work left. It was quite cool and the track took a bit to warm up - this is where that Michelin app came in handy - you could see how the tires were taking a bit to get up to temp. Looking forward to the coming weekend at Big Willow and more California track (I’ve been in SoCal 3 years and its time to get out and drive)

The Brembo GT-S holding up great, though Im nearing the end of the Ts-20 pads. Shocks are always there and the car just deliveres. 167k Miles and counting!

Overall the car handles great. I need to look at mitigating body roll somewhat and setting up with a track-only set of wheels and tires so I dont kill the street tires. Keep tuning the dampers and just get more seat time. Really want a set of seats and harnesses, but maybe just harnesses. Getting flung about is tiring.

Images by CaliPhotoVideo for SpeedDistrict

BMW e90 M3 LSL - Suspension

One hundred and thirty thousand miles on OEM shocks, bushings. Some of that with lowering springs installed by a previous owner. Time for a change.

The factory shocks with the lowering springs feel bouncy, with too much rebound or shot compression or just too much wear. The car crashes and rolls and just soft all around. To solve those problems the vehicle needs better bushings, better shocks and springs and better sub frame mounting.

With a wide variety of systems available I chose to work with MCS. Their shocks performed extremely well on some other builds with being very responsive, tunable and of high build quality. The valving works great and each adjustment has a significant change, impacting the overall feel. I did not want to deal with external reservoirs as the car would not see racing conditions to justify the components. Keeping in mind the goal of the vehicle and the LSL mentality - the setup had to be similar closer to what an OEM might come up with for a special model.

MCS offers the 2WNR shocks - which are 2 way adjustable (rebound and compression). The adjustment mechanism is quite unique in that the same little knob will do both, depending on position. You can click the knob down for one adjustment and release it upward for another. Easy.

The shocks are paired with Swift springs with front at 504lbs, with 168lbs helper and rear at 784lbs. This should provide enough compliance for roads and rougher tracks but also support the chassis well. Ground Control Race camber plates will secure the assembly along with their pivoting rear spring perches. The rear perches will pivot as the suspension travels, keeping the spring more square and not skewing the rate.

With better chassis control - need to ensure that there is minimal flexibility. Bimmerworld has a very comprehensive catalog of components to eliminate rubber and create a more direct chassis.

The rear subframe gets solid alum bushings along with the differential. Also eliminating the subframe side camber arm bushings in favor of nice sealed monoballs. The trailing arm bushings get replaced with a similar bushing. Also updating the front control arm rubber bushing to a monoball setup.

Bimmerworld uses nice sealed OEM like monoballs which will go a long way with reducing noise and increasing longevity. Monoballs are reliable and strong but most of the time they are exposed to the elements and wear prematurely - its not as relevant in motorsport due to increased service interval and more controlled conditions. BMW already uses monoballs on some suspension arms and I am merely finishing their job. A Porsche GT2RS (or 3RS ) does not have a single rubber bushing in the suspension, running the same sealed monoballs everywhere.

Im also adding adjustable drop links to aid in corner balancing the car (and the OE units are long dead) along with toe links. Ill address the bushings in the rear control arms at a later time if they prove to be too flexible.

One helpful note before installing coilovers is to measure the current ride height. This helps when resetting the car up, as you end up back in the ballpark of the alignment. This gives you the ability to use the car and have it drive more or less straight if you need to take it somewhere.

Getting new parts is fantastic, but installing them can be a “ride”. The rear subframe bushings are a real challenge. I decided to yank the subframe out with a friend, which was relatively easy. Using a press along with a lot of adapters and cylinders I got the bushings out, installed the Bimmerworld solid units. By the time that was done, we just wanted to get the thing back into the car.

I opted to do the rear monoballs, toe arms and diff mounts another time - for I could do those myself. Instead, we threw in the coilovers and set the car to previous ride height and camber. The trunk lining prevents easy access to the rear shock tower and over the tower itself was a rubber cover. I punched a hole in the trunk lining with a holesaw and re-used the rubber cap for a clean install. Easy access and looks intentional. The rear Ground Control spring adjusters are quite useful. Ride height tweaking is a breeze with easy tool access and a very effective design as the area is already so tight withouth easy tool access. No need to remove the wheels!.

Once the rear suspension upgrades are done, I will then corner balance the car and do a full alignment.

BMW e90 M3 LSL - Braking

The used M3 sedan came with 85k of unknown miles. There was a shimmy in the steering under hard braking and as in any case - its wise to review the braking systems on an any vehicle.

There was plenty of pad life, perhaps a recent update. The rotors were grooving a bit and some of the holes had started to form hairline cracks. I doubt this car was heavily tracked, but perhaps was a canyon carver? In any case - the shimmy was getting annoying and a refresh was in order.

I started looking at OE brake components, upgraded replacements and such and was disappointed with the direct replacement rotor options. I was looking for something that provided decent long terms serviceability and high quality that was't the OEM cross-drilled parts. The nicer units are priced fairly high like the PFC and StopTech products though are very nice pieces. There seem to be even less rear rotor options.

Now all this didn't even address the calipers, which I feel like are one of the shortcoming of this car. A decent rotor, pad, SS line and fluid combo goes a long way for track durability and longevity, though many still report fade and poorer performance.

The e90 M3 CRT was built with a set of Brembo calipers with some larger OE style rotors (perhaps Brembo as well?) which I found interesting. The 6-piston front and 4-piston rear setups seem like a much more logical solution for this platform. BMW shipped F30 and F80 platforms with mono bloc calipers from the factor, perhaps acknowledging the need and appeal. Since I am building this M3 as a road/track ready machine - I skipped over OE replacement upgrades and started speccing out a balanced brake system.

Criteria was simple: front and rear paired systems with great functionality and support for servicing, plug and play obviously with easy 18" wheel fitment. I also wanted something that wasn't a bright color. After looking at the market options I really liked the Brembo GT-R system with all the features and the nickel finish. Its quite a high dollar system which put it out of my range until I came across a new setup from Brembo - The GT-S Systems. The guys at Race Techonologies were very helpful in outlining the differences and benefits of this and how it falls between the GT and GT-R lines. The main being the pistons, featuring the higher grade heat exchange characteristics and no external dust seals. The exterior finish is a hard anodize black with the classic motorsport Brembo red lettering.

The kit I opted for was the smaller unit which ensured more wheel compatibility while maintaining great performance. Front rotors are at 365x34mm and the rears are 345x28mm and come with adapter brackets, hardware and stainless steel braided lines. Standard issue TS20 pads all around.

I flushed the whole brake fluid system, removed all OE pieces. Because I have OCD - the front and rear uprights got hosed with cleaners and the front dust shields were cleaned in the ultrasonic tank. Who knew they were gloss black! The Brembo pieces went on smooth and the install was finished off with some new Brembo HT64 brake fluid and a thorough flush.

Needless to say the build quality is great. The whole setup as an OEM-like look, disappearing into the shadows of the wheel. Braking is now massively predictable, consistent and stable. Modulating brake force is a lot easier with much better feedback from the system. I am very much looking forward to putting these to use on the track once some other bits get upgraded on the car.

BMW e90 M3 LSL - Wheel and Tire

The E90 M3 was presented with 220 Style 19" wheels which featured a machined face and a 10 spoke design. The Fuchs-manufactured design fits the platform very well, but they are heavy at 29lbs and a bit narrow.

Commonly underestimated - the wheel and tire combo massively affects performance of a chassis. Low rotating mass, good grip and wheel rigidity is essential.

A forged wheel is a must and I went looking for something in the 18" range. I really liked the Style 219 wheels in that gunmetal color with the concativity and spoke design, but they are still a bit conservative on widths. Combing through the usual offerings I stumbled across the Titan7 brand via EAS. The manufacturing specs were very good as well as the price point. My usual go-to would be the Apex wheels, as they are a staple and I've owned a set before, great wheels to daily on and not worry about. As with the day-job - we try to stay on top of new brands, tech and offerings. The people behind Titan7 have a vast history in the industry and track record. The products resonated with my own standards for detail, design and execution. My other choice would've been the Bimmerworld wheels, but I wanted to deviate from the classic design some. Ill be looking to pick up a set of 18x10 for a square track setup, but for now the 18x9.5 and x10.5 fitment is just right. The wheels are designed for the platform so no spacers are needed and they are light at about 19lbs each. (also easy to clean!)

The tires for a daily application were a no-brainer - Michelin. I opted for the PSS tires because at the time the PS4S was not available for the front size of 265/35R18 (rear is 285/35R18). In my mind - these PSS tires are a gold standard with great wet/dry condition and cornering performance. The car sees a 70 mile daily commute and they maintain a level of comfort and holding their ground when called upon.

BMW e90 M3 LSL - Refresh

Primary concern was the engine and its health. Oil analysis of what was inside when purchased was perfect, and now, about 5 oil changes later, its still consistently clean with no sign of excessive wear. The actuators were slowly failing and I replaced those with new units. All else on the engine is clean, with no leaks or issues.

I serviced the vehicle fully with new Motul engine oil (Xcess 10w60) and now most recently with Torco SR-5R with which it runs great. Have yet to do an oil test with the Torco, but seeing how it performs in the Porsche engines - I don't think there is much to worry about, especially with its MPZ chemistry.

Replaced the differential fluid with Motul and had a full DCT flush, filter and pan refresh done by the experts at Performance Technic when I visited the Bay Area along with a full alignment check.

Installed new plugs, cabin filters and new engine air filter on the pre-existing AFE intake as well. Suspension showed normal wear and tear and is slated for upgraded anyway. Brakes were worn out and I just recently overhauled the whole setup.

The felt undertray thing was pretty beat up and was missing one side. It seemed only logical to go with a metal unit and I opted for the Turner part. Very strong unit thats well designed and rigidly mounts to the bottom of the car. I've now scraped it a few times, but it holds up well.

The car is driven 70ish miles a day and runs like clockwork. Only major things left would be a coolant flush (with a cooling system upgrade) and power steering flush. Need to get the GTS DCT calibration done as well.

A full paint correction and ceramic pro treatment was completed by Polished Detail in Orange County which brought the Silverstone paint back to showroom look along with a deep shine. All the gloss black elements are back to new as well. Being skeptical at first - the ceramic pro layers really do wonders for keeping the LA dust and elements from sticking to the surface. A quick wash every week or two is a much easier affair with the right soaps. The wheels got a treatment too and its night and day with keeping them free of brake dust.

BMW e90 M3 LSL - Intro

BMW e90 M3 LSL

Limousine Sport Leichtbau

2009-10-21

2010 BMW M3 Sedan

4.0L V8

DCT

Silverstone Metallic II

Novillo Palladium Silver

The BMW CSL vehicles were based on coupes with performance and weight reduction enhancements. Over the years BMW has made a few special sedans like the E90 CRT and now the F80 CS which follow the same mentality. I was always attracted by the notion of minimal, performance oriented machines like the E46 CSL and the spartan GT3 Porsche which maintained street sensibility with full track readiness.

While the E90 M3 CRT was a great technical exercise in carbon technologies it was still a fully loaded sedan which, in my mind, contradicted its purpose. It is also unobtainable. The sedans are unique, well proportioned vehicles. The S65B40 is a phenomenal engine, clearly built with purpose with the large intake, port matched individual throttle bodies and equal length headers. When paired with the DCT makes for quite the driving machine. Being around the Porsche PDKs brought me over to the double clutch world. The BMW DCT is a very solid unit, especially with the GTS update. My only real preference when seeking out the E90 M3 was to have minimal options along with the DCT transmission. I also liked the Silverstone Metallic II color as its less common and quite elegant in person. A 2010 sedan with 85k miles popped up with the sunroof and the leather seats as the only things I didn't care for. The car had failing throttle actuators which were an easy replacement and needed some general maintenance to refresh critical components. It came with lowering springs, primary cat delete and “exhaust mod”. It’s almost the perfect platform to start with to build the e90 M3 LSL (Limousine Sport Leichtbau). Its a sedan based nod to the CSL and how I believe the CRT could’ve been to some extent.

I am a professional working in the automotive aftermarket and motorsport industry and this is my personal R&D project building an e90 M3 LSL.

Consulting Life. Interview with GrabCAD

To make the most of limited resources it is always good to be aware of emerging technologies and systems to potentially help streamline work flow. CAD software, file management, 3D printing software and anything else related that is going through a lot of changes. Cloud computing and cloud storage solutions are more powerful than ever before. Generally speaking, the usual industry leaders take time to adapt which gives smaller entities a narrow opportunity to bring to market something new and truly innovative.

GrabCad was one of those companies that offered a set of services that I think will help shape how CAD files are managed, stored and printed. I have been a long time user of the GrabCad libraries, built up by fellow CAD users and I've started to try and incorporate GrabCAD Workbench as a PDM alternative.

The latest addition is GrabCAD Print, which I have implemented over at 034Motorsport. The standard, outdated software that worked with their Stratasys Dimension printer did the job, but was cumbersome and old. Since GrabCAD print is partnered with Stratasys - they have perfect support for these printers. Its intuitive and easy to use and I like seeing how far along the printer is or if it ran run out of material and needs reloading.

The team at GrabCAD reached out to talk about what I do, consulting and technology and did a small interview blog post. I look forward to seeing what other products and updates they have in the pipeline so hopefully we will have more conversations about how their software helps us CAD designers think outside the bounding box.

Link to article: http://blog.grabcad.com/blog/2017/02/13/start-engineering-consulting-business-little-help-3d-printing-grabcad/

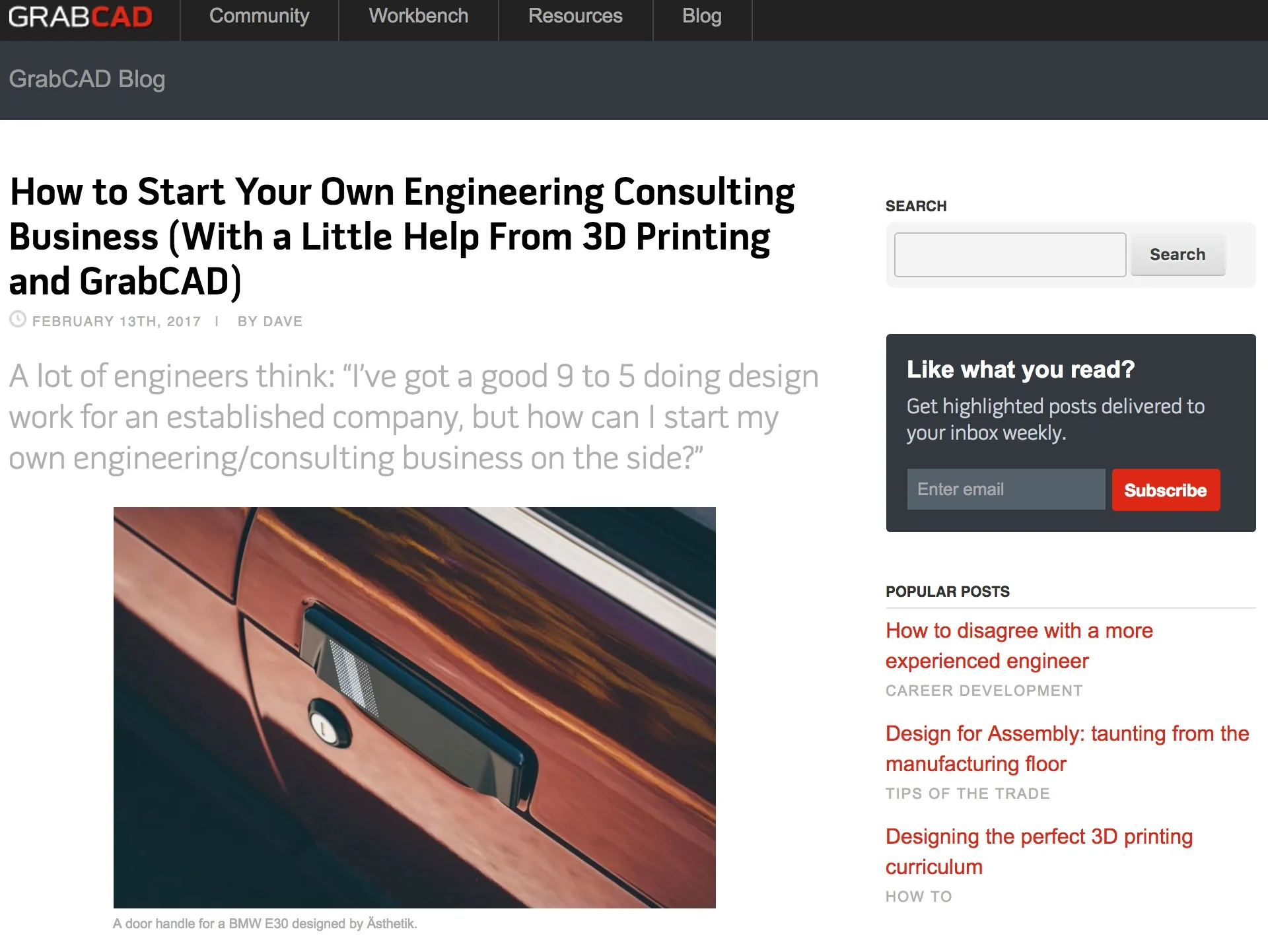

Perfect Start. Ästhetik, Petrolicious and good things to come.

Ästhetik was created to be a creative outlet, to apply design and to keep a boutique brand that doesn't need to be scalable, have a distribution network and be constantly crosschecked by the bean counters. (www.auto-asthetik.com)

Nick Caron and I came together on this with the same mindset and expectation. Our first product is a door handle for the E30 generation of BMW 3-Series and it goes against what would be considered a reasonable part for cars that old. We had gone through various scenarios of how our brand would launch and how this first part would be received.

Needless to say - all of our expectations were surpassed. Igor at CAtuned was kind enough to help us hit the ground running, our instagram content is well received and Ted Gushue was generous to get our creation featured on Petrolicious.

Everything came together so well. We are now looking to maintain some of that momentum and bring forth new products in the same spirit. We hope they will be just as well received. In the meantime - thank you to all that helped and supported us though it.

Here is the link to the Petrolicious article:

http://petrolicious.com/redesigned-bmw-e30-door-handles-are-our-kind-of-overkill

Interrupt Design, Not Power

The surge protector, the power strip all seem to have had make-overs to make them more appealing and presentable. Why not apply it to the average UPS units, and then some?

These big black boxes are stuffed under desks everywhere and they play quite the vital role in ensuring that work continues. Many times have these things saved us from not saving in time. While these units are, no doubt, useful, the common uninterruptible power supplies seem to not have changed since the dawn of personal computers. Mainstream units still sport the early 90s design aesthetics and they seem to eat batteries, especially when its most inconvenient. Until there is wireless power transmission, we most likely won’t be able to get away from these things anytime soon.

Here is an idea.

Homes and offices are starting get connected with small networks that monitor and control the utilities and basic fixtures. Lights, outlets, HVAC systems all can be programmed to run when they are needed and how they are needed: at peak efficiency. Feedback from devices provides insight into usage, prevents too much usage and early alerts prevent issues. Modern battery tech has advanced greatly as well. Chargers monitor best charge rates and smart batteries report back usage, charge cycles and other data which helps keep them operating at max capacity for longer.

This UPS would hook right in to the automation networks and the internet. It monitors whatever is plugged in, reports on usage and allows for the control of each outlet. If there is a power loss, the unit would do its best to report on it and log the event. Intelligent battery monitoring and charging is the more important feature. Diligent battery management results in less frequent batt. replacements and provides advance warnings on potential failures. With the UPS being connected to the web, it can send out maintenance requests as needed preventing downtime at the wrong time. This is similar to how a car monitors its own battery health – why not do it with every battery?

If the UPS is going to provide power, why not have it do so over USB as well. Charging USB devices should not be dependent on the power state of the computer nor should it demand yet another thing plugged into the wall. A small USB power point is a way to bring USB charging to the desktop, within easy reach for quick power-ups. The power point grabs power from the same USB ports on the main unit and features small LED lights to show basic UPS status.

The clean design is meant to allow one to keep this UPS on the floor and visible without shame. The unit does also has provisions for wall mounting or even under-table mounting to tuck it out of view. A cradle gets attached where ever desired and the unit clips in.

There is no need to re-invent the wheel. All the technology is readily available. There are UPS units, smart battery tenders, USB chargers and home automation adapters. Why not simplify things a bit, merge and save some wires, plugs, outlets and batteries. After all, less is more.

3D Printing: The Industrial Revolution

It is no secret that the future is here with 3D printing. As Shapeways so well puts it in their slogan “Made in the Future” – this technology is becoming very accessible with an exponential rate of development. The ability to create objects straight from a computer model has revolutionized many engineering and manufacturing processes. Cutting costs and time, 3D printing has also made complex manufacturing more accessible to smaller businesses. By printing prototypes of castings, for example, engineers no longer need to wait on costly cast samples to verify designs. Most of the time, a printed model can be used to confirm and initiate a production run of components (and assist the casting company in making the tooling). 3D printing can even be used to create single-use moulds to “rapid cast” a part if real-world application testing is needed. This process for prototyping and validation can be applied to parts from any material or manufacturing method.

The Revolution

For now, the 3D printing process is mostly used for prototyping or on demand production of smaller, simpler plastic parts or even jewelry. The real impact of the technology is when it is more advanced and cheaper – as any technology becomes with mass market demand and implementation.

Plaster or plastic based 3D printing is most common and cheapest at the moment. Metal based 3D printers are coming online as well, used more in aerospace, defense and advanced research industries – is also the most expensive process. With the evolution of current printers and with the development of “mixed media” ones, factories will be upgrading and replacing existing assembly lines, machinery and tooling with an array of 3D printers.

3D printing will become the faster, cheaper way to make things. Part-specific tooling and machinery will be eliminated and re-tooling will consist of just uploading a new file. Once printers start to mix media – a single printer will be able to produce a whole device, with metallics, plastics and electric circuitry. Ultimately food and human tissue will be printed as well (research is already underway).

Applicable

These are the kinds of technological advances that define the future and impact not just specific industries – but change the world. We are excited to use these systems with our current projects and develop new products to take advantage of 3D printing, not just for prototyping, but as the primary manufacturing technique.

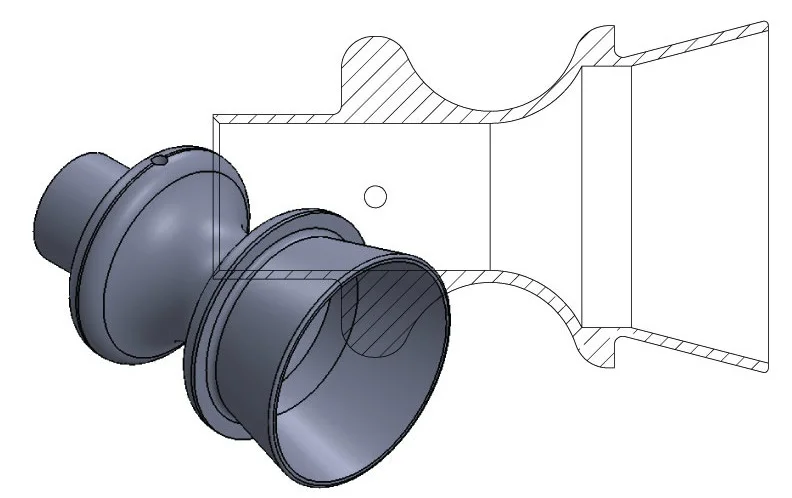

One of our current projects is based around a simple OEM part requiring basic reverse engineering, tweaking and manufacturing out of a different, premium material. Originally made of injection moulded ABS plastic, our client was looking to manufacture it out of aircraft grade aluminum. This change in material would make the part have a more solid, smoother feel with better aesthetics.

We used 3D printing to validate the specs to ensure OEM-like fitment and to get a “feel” for the small aesthetic design changes to the original OEM configuration. Once verified – the production run was started. The final manufacturing process is CNC lathe turning and anodizing for the final finish.

Wells Blog

Duis mollis, est non commodo luctus, nisi erat porttitor ligula, eget lacinia odio sem nec elit. Maecenas faucibus mollis interdum. Nulla vitae elit libero, a pharetra augue.